Choosing the wrong solar water pump can ruin your irrigation project. I’ve seen costly mistakes derail farms. Here are five truths to guide your selection process.

Common mistakes in solar pump selection include ignoring flow needs, underestimating solar reliance, poor pipeline design, prioritizing cheap pumps, and neglecting system compatibility. Submersible sewage pumps work best for sediment-heavy river water.

Let’s dive into these errors with real-world cases to help you make smarter choices for your agricultural or project needs.

Mistake 1: Focusing Only on Pump Power, Ignoring Actual Flow Requirements?

A farmer I worked with bought a 750W pump, expecting it to irrigate 30 acres. It failed. Why? He ignored head height and pipeline friction.

The rated power of a solar pump doesn’t guarantee water output. Flow depends on head height, pipeline design, and solar input. Calculate water demand based on irrigation area and usage.

Why This Happens

Many assume higher wattage equals more water. But total dynamic head—vertical lift plus friction—reduces flow. Long pipelines or high lifts can cripple even powerful pumps. I once helped a client who misjudged his well’s depth, leading to dry crops despite a pricey pump.

How to Avoid It

Start with your project’s needs. Measure:

- Irrigation area (e.g., hectares)

- Daily water volume

- Usage frequency

Use online flow calculators or consult engineers. For example, a 10-acre farm might need 20 m³/hour, but a 50-meter head reduces output. Match the pump to these specifics.

| Factor | How to Assess |

|---|---|

| Irrigation Area | Calculate based on crop water needs |

| Head Height | Measure vertical lift + pipeline friction |

| Usage Frequency | Estimate daily or seasonal water demand |

This approach ensures your pump meets real-world demands, saving you from underperforming systems.

Mistake 2: Assuming Solar Pumps Work Efficiently in All Weather Conditions?

I saw a Nepalese farm struggle with a high-power pump. Cloudy skies left their crops dry, as the system couldn’t run consistently.

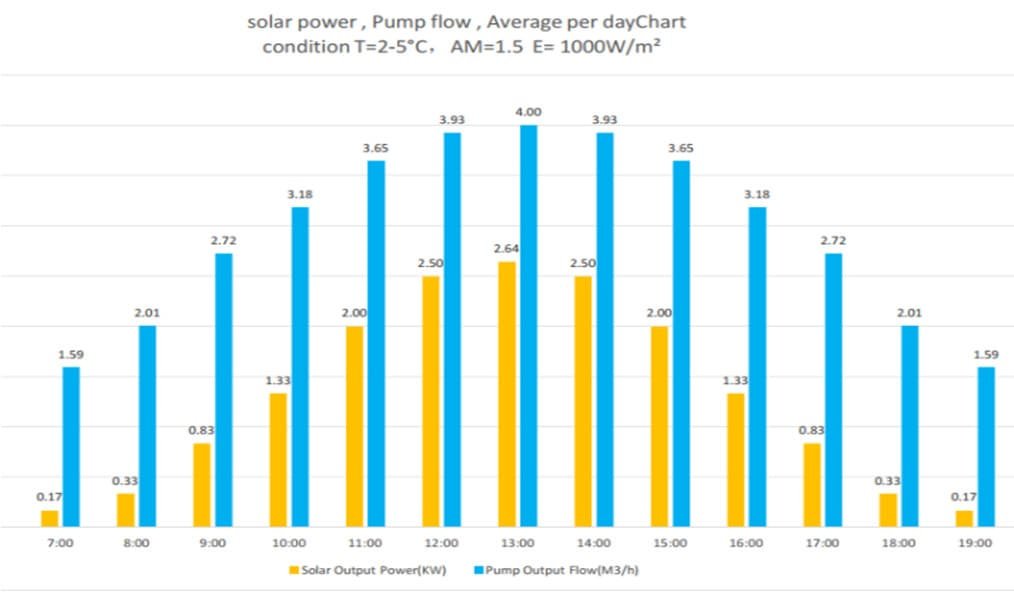

Solar pumps depend on sunlight. Cloudy weather or low morning light cuts power, reducing pump performance. Check local solar data and use inverters to optimize energy.

Why This Happens

Solar pumps rely on photovoltaic panels, which need direct sunlight. In areas with frequent clouds or short daylight, output drops. I recall a project where the client didn’t account for monsoon season, leading to irrigation failures.

How to Mitigate It

Study local weather:

- Average sunlight hours (e.g., 5–8 hours/day)

- Peak irradiance levels

Pair pumps with inverters that adjust to low light. Oversizing panels can help. For example, a 1kW pump might need 1.2kW of panels in cloudy regions to maintain flow.

| Factor | Action |

|---|---|

| Sunlight Hours | Check historical weather data |

| Peak Irradiance | Use solar maps for your region |

| Inverter Optimization | Select models with low-light performance |

Planning for weather variability ensures your pump works year-round, even in tough conditions.

Mistake 3: Ignoring Pipeline Design’s Impact on Pump Performance?

A client once complained about low water output. The issue? Poorly designed suction pipes caused cavitation, damaging the pump.

Pipeline design affects pump efficiency. Poor suction lines cause resistance, air intake, or cavitation, reducing flow and damaging equipment. Always optimize pipe layout.

Why This Happens

Pipelines aren’t just tubes—they impact flow dynamics. Bends, narrow pipes, or air leaks increase resistance or cause cavitation, where air bubbles collapse and harm impellers. I’ve seen projects fail because installers used cheap, undersized pipes.

How to Fix It

Design pipelines carefully:

- Use straight, wide suction lines

- Avoid sharp bends or excessive elbows

- Seal pipes to prevent air leaks

For a 1kW pump, a 2-inch pipe might suffice, but long runs need wider diameters. Proper design boosts efficiency and extends pump life.

| Pipeline Issue | Solution |

|---|---|

| High Friction | Use wider pipes, minimize length |

| Cavitation | Ensure proper suction depth, avoid air leaks |

| Sharp Bends | Use smooth curves, fewer elbows |

Good pipeline design is as critical as the pump itself for reliable water delivery.

Mistake 4: Believing Cheaper Pumps Offer Higher Cost-Effectiveness?

A project I advised on used budget pumps. Within months, sand and corrosion wrecked them, doubling costs with repairs.

Cheap pumps often use low-quality materials, leading to corrosion or failure in harsh conditions. Investing in durable pumps saves money long-term.

Why This Happens

Low-cost pumps cut corners on materials—think weak stainless steel or poor seals. In sediment-heavy or acidic water, they fail fast. I’ve seen farmers replace cheap pumps yearly, erasing initial savings.

How to Choose Wisely

Evaluate:

- Water quality (pH, sediment levels)

- Environmental conditions (e.g., heat, dust)

- Manufacturer reputation and warranties

For river water with debris, submersible sewage pumps handle sediment better. Quality pumps cost more upfront but last years longer.

| Consideration | Why It Matters |

|---|---|

| Water Quality | Sediment or acidity can corrode cheap pumps |

| Environment | Heat or dust can degrade low-quality motors |

| Manufacturer | Reliable brands offer better support, longevity |

Investing in quality prevents downtime and costly replacements.

Mistake 5: Ignoring Overall System Matching, Purchasing Pumps Separately?

A client bought a three-phase pump but paired it with an undersized inverter. The system struggled, wasting energy and water output.

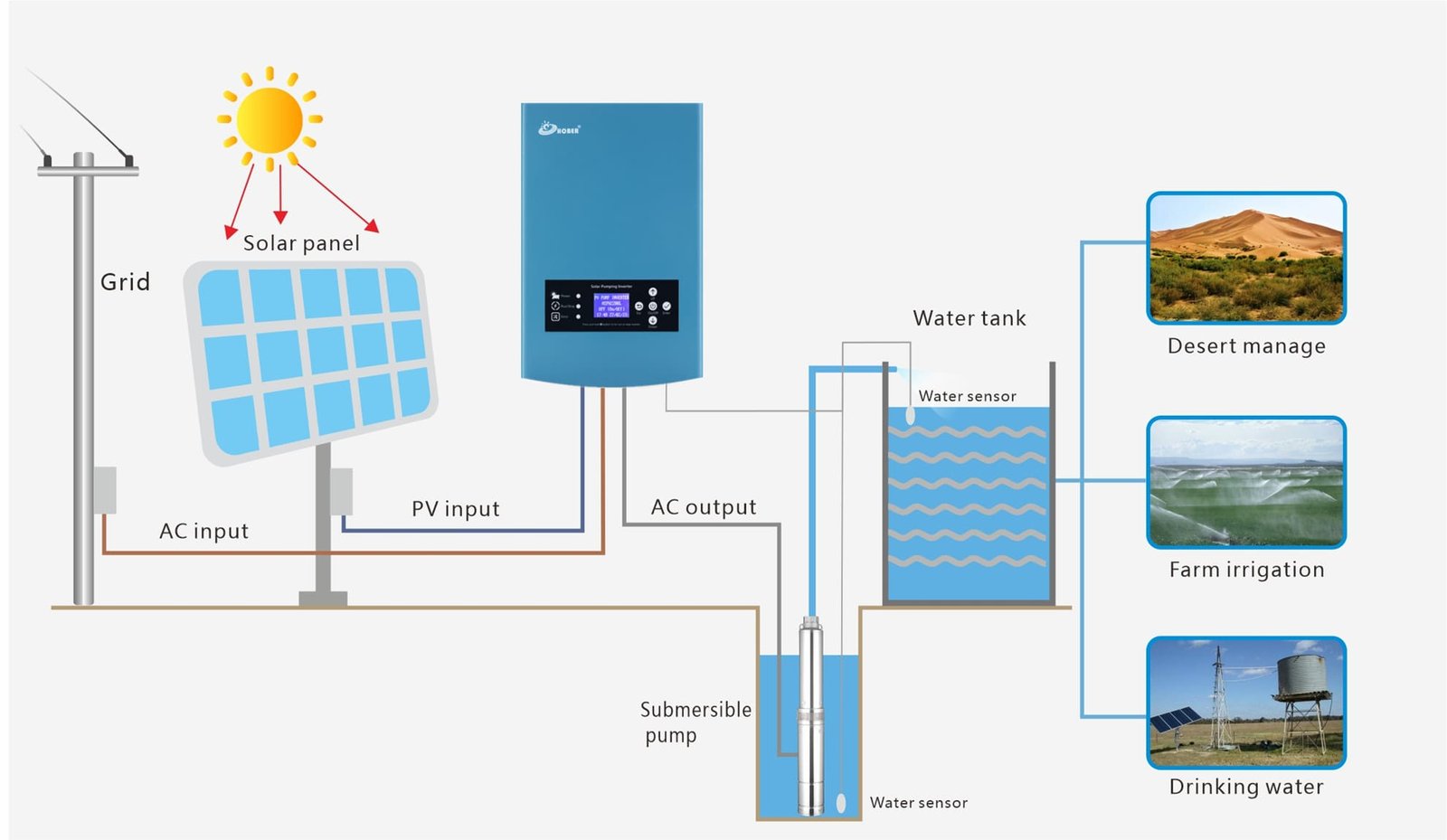

Solar pump systems need matched components—panels, inverters, and motors. Mismatched parts cause inefficiency or failure. Always design the system holistically.

Why This Happens

Pumps don’t work alone. Panels provide power, inverters control it, and motors drive the pump. Incompatible parts—like an inverter too weak for startup—reduce performance. I’ve seen projects stall because distributors sold pumps without system advice.

How to Ensure Compatibility

Check:

- Panel capacity matches pump power needs

- Inverter handles startup current

- Motor type (AC/DC) aligns with the system

For a 1.5kW pump, you might need a 2kW inverter and 1.8kW panels. System-level planning prevents energy loss.

| Component | Matching Tip |

|---|---|

| PV Panels | Size 30–80% above pump power needs |

| Inverter | Must handle peak startup current |

| Motor | Match pump type (AC/DC) to inverter |

A matched system ensures efficiency and longevity.

Conclusion

Avoid these five mistakes—ignoring flow, weather, pipelines, cheap pumps, and system mismatch—for a reliable solar water pump. Submersible sewage pumps excel for river water projects.