Switching from traditional electric pumps to solar power offers significant benefits, including cost savings and environmental sustainability. For engineers and DIY enthusiasts alike, converting existing single-phase or three-phase pumps to solar-powered systems can be an efficient and rewarding process. This guide will walk you through how to convert both 220V single-phase and 380V three-phase pumps into solar-powered pumps, focusing on the technical requirements and best practices for ensuring smooth operation.

Converting Electric Pumps to Solar: An Overview

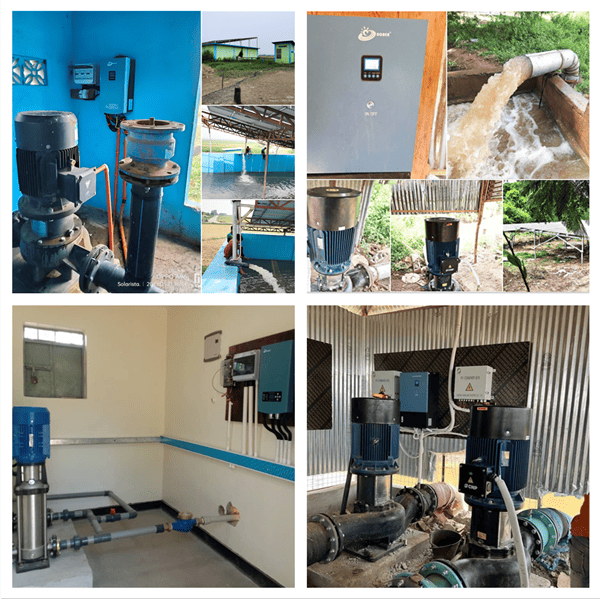

The key to successfully converting a traditional electric pump to a solar-powered system lies in using solar pump inverters. These devices take the DC (direct current) power generated by solar panels and convert it into the AC (alternating current) required by most electric pumps. Depending on the type of pump (single-phase or three-phase), the conversion process may vary slightly.

Converting a traditional single-phase or three-phase motor to solar can be achieved using specific kits, like solar pump inverters, which ensure compatibility and smooth motor operation. The solar inverter takes over the motor starting process and converts the DC energy from the solar panels into the necessary AC voltage to power the pump.

Can You Convert an Electric Pump to Solar?

Yes, converting an electric pump to solar is not only possible but also relatively straightforward with the right equipment. Whether you have a single-phase or a three-phase pump, the process typically requires a solar pump inverter, which replaces the grid electricity with solar power.

For single-phase pumps, the inverter handles both the motor starting and running processes. In this case, you must remove the pump’s internal capacitor because leaving it in the circuit may cause compatibility issues with the inverter. The inverter manages the pump’s electrical characteristics, rendering the capacitor unnecessary.

For three-phase pumps, the conversion is even simpler. These pumps do not have internal capacitors that need removal, meaning they can connect directly to the solar inverter. The inverter will convert the solar panel’s DC output to the correct AC voltage and frequency required by the pump, allowing for seamless operation.

Can I Connect a Pump Directly to a Solar Panel?

No, directly connecting a pump to solar panels is not advisable. A solar pump inverter is necessary to convert DC power to AC for the pump to function correctly. Solar panels produce DC energy, while most electric pumps are designed to run on AC. Without an inverter, the electrical mismatch would render the pump inoperable and potentially damage both the pump and the solar panels.

The inverter’s job is to ensure that the voltage and current from the solar panels are converted and optimized for the pump’s requirements. This ensures that your system operates efficiently, even when solar energy fluctuates throughout the day due to changes in sunlight intensity.

How Do Solar Pump Inverters Work?

A solar pump inverter converts the DC electricity generated by solar panels into the AC power needed by your pump. This conversion process is vital for both single-phase and three-phase pumps, and it ensures that the correct voltage and frequency are delivered to the pump motor.

For single-phase pumps, the inverter also takes over the pump’s starting process, which is traditionally managed by a capacitor. By handling the motor start-up, the inverter eliminates the need for the capacitor, ensuring smooth and efficient operation without compatibility issues.

For three-phase pumps, the inverter converts the DC power to the correct three-phase AC voltage and frequency required by the motor. This conversion happens seamlessly, meaning you don’t need to modify the pump’s internal components.

Why Remove the Capacitor in Single-Phase Pumps?

In traditional single-phase electric pumps, capacitors play a crucial role in starting the motor and keeping it running efficiently. However, when converting these pumps to solar power, the inverter handles the motor starting function, making the capacitor unnecessary.

Leaving the capacitor in the circuit can cause problems, such as compatibility issues between the inverter and the pump motor. The inverter is designed to work without the capacitor, and removing it helps ensure smooth operation. Once the inverter is installed, it takes full control of the electrical characteristics needed to start and run the motor.

How to Connect a Three-Phase Pump to Solar?

Converting a three-phase pump to solar power is a simpler process compared to single-phase pumps. Here’s a step-by-step guide on how to do it:

- Install Solar Panels: The first step is to set up your solar array. Make sure that the solar panels are sized correctly to meet the power requirements of your pump. Typically, a professional will calculate the total wattage needed based on the pump’s horsepower and daily operational needs.

- Choose the Right Solar Pump Inverter: Select a solar pump inverter that matches the pump’s voltage and power rating. For 380V three-phase pumps, choose an inverter that can handle three-phase power output.

- Connect the Solar Panels to the Inverter: The solar panels will produce DC power, which needs to be fed into the solar pump inverter. Connect the positive and negative terminals from the solar array to the inverter input terminals.

- Connect the Inverter to the Pump: Once the inverter is receiving power from the solar panels, it will convert the DC power to AC. Connect the output of the inverter to the pump’s input terminals, ensuring that the connections match the pump’s three-phase configuration.

- Test the System: After all connections are made, run a test to ensure that the system operates smoothly. The inverter should automatically adjust the power based on sunlight availability, keeping the pump running efficiently throughout the day.

Differences Between Solar Pump Systems and Traditional Pump Systems

When considering converting a traditional pump system to a solar pump system, it’s important to understand the key differences between the two. Whether in terms of energy sources, installation complexity, or maintenance, solar pumps and traditional pumps offer different advantages and trade-offs.

1. Energy Source

- Traditional Pump Systems: These systems rely on grid electricity or diesel generators. Electric pumps require a consistent supply of AC power, while diesel pumps need regular refueling. This makes them dependent on external energy supplies, with ongoing energy costs.

- Solar Pump Systems: Solar pump systems utilize sunlight as their primary energy source. Solar panels capture sunlight and convert it to DC power, which is then transformed into AC by a solar inverter to drive the pump. Since solar energy is free, these systems can operate at virtually no cost during daylight hours, as long as there is sufficient sunlight.

2. Running Costs

- Traditional Pump Systems: These systems incur higher operating costs due to their reliance on grid electricity or diesel fuel. Rising fuel prices or electricity tariffs can further increase operational expenses over time.

- Solar Pump Systems: Solar-powered systems have minimal running costs after installation. Since the energy comes from the sun, there are no fuel or electricity bills to worry about. The only costs associated with solar pumps are for periodic maintenance, such as cleaning the solar panels.

3. Environmental Impact

- Traditional Pump Systems: Pumps powered by grid electricity often contribute to carbon emissions if the electricity is generated from fossil fuels. Diesel-powered pumps also release pollutants into the atmosphere.

- Solar Pump Systems: Solar pumps are an environmentally friendly alternative, as they rely on renewable solar energy. These systems produce no carbon emissions, reducing the environmental footprint and supporting sustainability efforts.

4. Reliability and Suitability

- Traditional Pump Systems: In remote areas or places with unreliable grid power, traditional electric pumps may face operational issues. Power outages or fuel shortages can disrupt the pump’s operation and affect water supply.

- Solar Pump Systems: Solar pump systems are highly reliable, especially in regions with abundant sunlight. They provide a dependable water supply as long as the sun is shining. In areas with inconsistent sunlight, the system can be paired with batteries to store energy for use during cloudy days or at night.

5. Installation and Maintenance

- Traditional Pump Systems: Installation of traditional pump systems is typically straightforward but requires connection to the electrical grid or fuel supply. Maintenance can be more frequent, particularly for diesel-powered pumps, which require regular fuel refills and servicing.

- Solar Pump Systems: While solar pump systems require more complex initial setup, including the installation of solar panels and inverters, they have lower long-term maintenance needs. Regular cleaning of the solar panels to maintain efficiency is generally the primary maintenance task.

6. Return on Investment

- Traditional Pump Systems: The initial cost of traditional pumps is generally lower, especially in areas with easy access to grid power. However, long-term costs increase due to electricity or fuel consumption, making them more expensive over time.

- Solar Pump Systems: Solar pump systems have a higher upfront cost due to the purchase of solar panels and inverters. However, once installed, the system operates at minimal cost, allowing users to recover their investment over several years. In the long run, solar systems prove more cost-effective.

Summary

Converting traditional electric pumps to solar-powered systems is an excellent way to reduce energy costs and contribute to a greener environment. For single-phase pumps, removing the capacitor is essential, as the solar inverter takes over the motor starting process. For three-phase pumps, no internal modifications are necessary, as the inverter seamlessly converts DC power to the appropriate AC voltage.

Understanding the differences between solar pump systems and traditional pump systems can help you make an informed decision. Solar systems offer lower operating costs, greater sustainability, and improved reliability in off-grid areas, making them a valuable investment for long-term water pumping solutions.