As the CEO of HOBER, a leader in the solar pump inverter industry, I’ve seen firsthand the impact quality control has on our products and, ultimately, on our business success. Quality isn’t just a buzzword for us; it’s the cornerstone of our operations, especially in a market as competitive and dynamic as ours.

Quality in solar pump inverters isn’t just about meeting standards; it’s about exceeding them. At HOBER, we go the extra mile to ensure our inverters aren’t just good but are the best on the market. How do we achieve this? Let’s dive in.

In a world where renewable energy sources are increasingly crucial, the role of solar pump inverters has never been more significant. They are the heart of solar water pumping systems, and their reliability can make or break the efficiency of the entire setup. But how do we, at HOBER, ensure each inverter that leaves our factory is top-of-the-line?

What Does Quality Mean for Solar Pump Inverters?

Quality for us means reliability, efficiency, and longevity. Every solar pump inverter must pass through rigorous testing phases to ensure these attributes. We focus on three critical testing processes: Semi-finished Product Testing, Load Testing, and Aging Testing. Let me take you through each.

Semi-finished Product Testing: Why Is It Crucial?

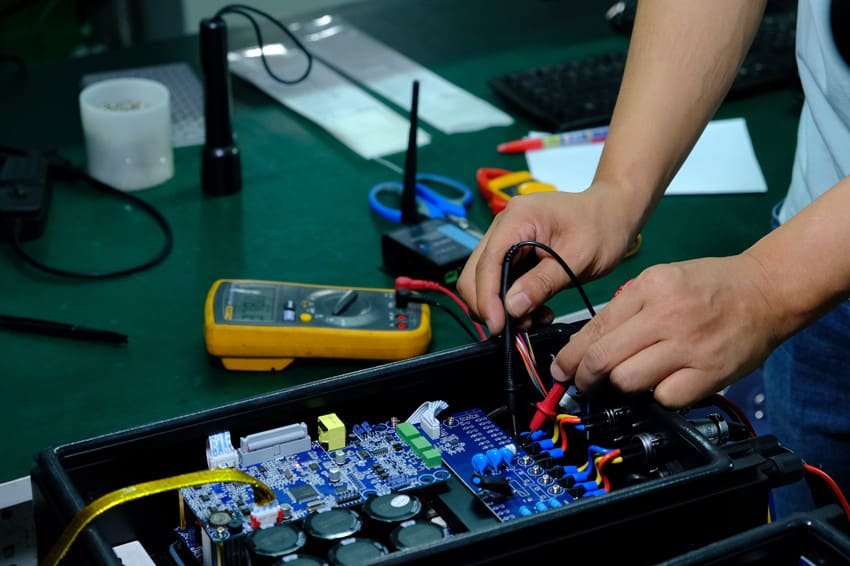

In Semi-finished Product Testing, we scrutinize each component. This isn’t just about ticking boxes; it’s about ensuring each part functions perfectly in harmony with others. This stage is crucial in detecting any potential issues early on. We conduct electrical safety tests, efficiency checks, and more to ensure every component meets our high standards. Learn more.

Load Testing: How Do We Mimic Real-world Conditions?

Load testing is where we simulate various operational conditions. It’s like putting the inverter through a fitness test – can it handle the pressure? From maximum to fluctuating loads, this testing phase ensures our solar pump inverters perform consistently under all circumstances. This step is vital for the reliability that our clients, like those in Africa and Southeast Asia, heavily rely on.

Aging Testing: Ensuring Longevity

How long will our inverters last? Aging testing helps us answer this. By subjecting our products to various environmental conditions, we simulate years of usage. This process is critical in predicting the inverter’s lifespan and assuring our customers of its long-term reliability. It’s not just about surviving; it’s about thriving over time.

The Bottom Line: Why Do These Tests Matter?

Quality control is not just a procedure; it’s a promise – a promise to our customers that every HOBER inverter is robust, reliable, and ready for the long haul. In the dynamic markets of solar energy, particularly in regions like Africa, the Middle East, and South America, this promise is our bond with customers.

As we continually evolve and adapt our testing processes, we stay ahead of the curve, not just meeting but setting industry standards. It’s not just about being good; it’s about being the best.

Conclusion

In the end, it all boils down to trust. Every test we conduct, every standard we exceed, is to build and maintain that trust with our clients. As a leader in this field, I take pride in the fact that our rigorous quality control processes are a significant reason why our clients choose HOBER again and again.