Pump systems are critical in various industries, but choosing the wrong inverter can lead to inefficiency, higher costs, and system failures. What factors should you consider to ensure the right inverter for your pump?

Choosing the right inverter is crucial for pump systems because it directly impacts efficiency, cost control, and system longevity. A mismatched inverter can result in frequent breakdowns, higher energy consumption, and increased maintenance costs.

Selecting the right inverter requires understanding your pump’s requirements and the specific conditions of your installation site. Let’s explore this in detail.

Why Choosing the Right Inverter Matters for Pump Systems?

A poorly chosen inverter can lead to system failures and increased operational costs. Why should you prioritize the right inverter for your pump system?

The right inverter ensures optimal pump performance, reduces energy consumption, and extends the system’s lifespan. It also minimizes maintenance costs and avoids frequent downtimes, which can disrupt operations.

Cost Control with Proper Inverter Selection

Proper inverter selection helps control costs by reducing energy consumption and preventing frequent repairs. Matching the inverter to the pump’s power requirements ensures efficient operation, lowering electricity bills and maintenance expenses.

Field Installation & Commissioning Efficiency

A compatible inverter simplifies installation and commissioning. It reduces setup time and avoids compatibility issues, ensuring a smooth start for your pump system 1.

Types of Pumps and Their Inverter Requirements

Different pumps have unique inverter needs. What are the inverter requirements for common pump types?

Centrifugal pumps, submersible pumps, deep well pumps, and screw pumps each have specific inverter requirements. Matching the inverter to the pump type ensures efficient and reliable operation 2.

Centrifugal Pumps

Centrifugal pumps typically require inverters with soft-start capabilities to handle their high initial torque. The inverter must match the pump’s power and voltage requirements.

Submersible Pumps

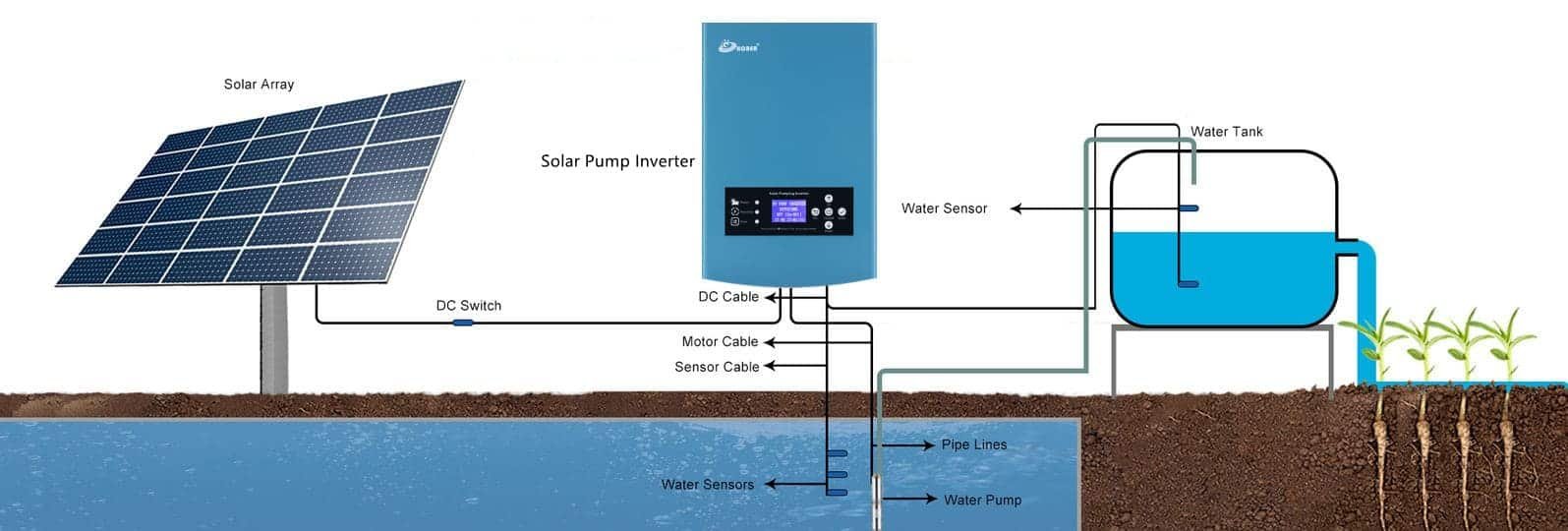

Submersible pumps often operate in harsh environments, requiring inverters with high IP ratings for protection against water and dust. They also need inverters that can handle variable loads efficiently.

Deep Well Pumps

Deep well pumps require inverters with high efficiency and robust performance to handle the challenges of deep water extraction. The inverter must support continuous operation and manage high-pressure loads.

Screw Pumps

Screw pumps need inverters with precise control capabilities to maintain consistent flow rates and pressure. The inverter should also handle high torque demands.

5 Key Factors to Consider When Selecting an Inverter

Choosing the right inverter involves evaluating several factors. What are the most critical considerations?

The key factors include matching pump power, voltage compatibility, environmental conditions, control features, and compliance with certifications. These ensure the inverter meets your system’s needs 3.

Matching Pump Power & Inverter Capacity

The inverter’s power rating should match or slightly exceed the pump’s power requirements. Oversizing or undersizing the inverter can lead to inefficiency or system failure 4.

Grid Voltage & Environmental Conditions

Consider the grid voltage and installation environment when selecting an inverter. Ensure the inverter can operate in indoor or outdoor settings and has the appropriate IP rating for protection against dust and water.

Start-Up Methods

The inverter should support the pump’s start-up method, whether soft-start or direct start. Soft-start inverters reduce mechanical stress and prolong pump life.

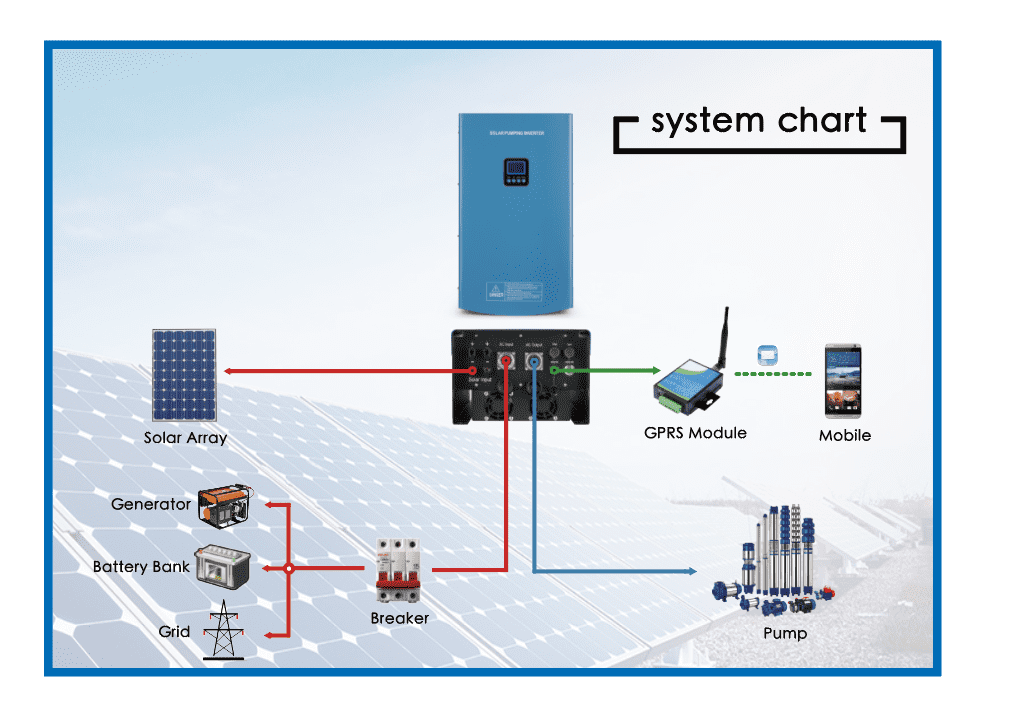

Control Features

Advanced control features like MPPT (Maximum Power Point Tracking) and PID (Proportional-Integral-Derivative) control enhance system efficiency and performance. Remote monitoring capabilities are also beneficial.

Certifications & Standards

Ensure the inverter meets industry standards like CE, IEC, and ROHS. Compliance with these certifications guarantees safety, reliability, and environmental sustainability 5.

Common Mistakes in Pump Inverter Selection and How to Avoid Them

Incorrect inverter selection can lead to costly mistakes. What are common errors, and how can you avoid them?

Common mistakes include selecting the wrong power rating, ignoring environmental factors, and overlooking certifications. Avoiding these errors ensures optimal pump system performance 6.

Incorrect Power Rating Selection

Selecting an inverter with a power rating too low or too high can cause inefficiency or damage. Always match the inverter’s capacity to the pump’s requirements.

Ignoring Environmental Conditions

Failing to consider the installation environment can lead to inverter failure. Choose inverters with appropriate IP ratings for protection against dust, water, and temperature extremes.

Overlooking Certifications

Ignoring certifications can result in non-compliance with safety and environmental standards. Always ensure the inverter meets industry certifications like CE and IEC.

Market Trends & What Installers and Distributors Should Know in 2024

The pump inverter market is evolving. What trends should installers and distributors be aware of in 2024?

In 2024, the demand for energy-efficient inverters1 with advanced control features and remote monitoring capabilities will increase. Installers and distributors should focus on offering sustainable and cost-effective solutions.

Energy Efficiency & Sustainability

Energy-efficient inverters will dominate the market due to rising energy costs and environmental concerns. Inverters with MPPT and PID controls will be in high demand.

Remote Monitoring & Smart Controls

Remote monitoring and smart control features are becoming essential for pump systems. These technologies enable real-time performance tracking and reduce maintenance downtime.

Differentiated Procurement Strategies

Installers and distributors should adopt differentiated procurement strategies to cater to diverse customer needs. Offering customizable inverter solutions will provide a competitive edge.

Case Study: How Installers in Kenya Optimized Their Projects with the Right Inverter

Real-world examples illustrate the importance of proper inverter selection. How did Kenyan installers optimize their projects?

In Kenya, installers achieved significant efficiency improvements by selecting inverters tailored to local conditions. This resulted in reduced installation times, lower operational costs, and fewer post-installation issues.

Project Background

The project involved installing solar-powered pump systems for agricultural irrigation in rural Kenya. The challenging environment required robust and efficient inverters.

Solution & Results

Installers selected inverters with high IP ratings, MPPT controls, and compatibility with local grid voltages. This choice improved system efficiency, reduced installation time, and minimized post-installation problems.

Conclusion

Choosing the right inverter for your pump system is critical for efficiency, cost control, and longevity. By considering power requirements, environmental conditions, and certifications, you can ensure optimal performance.

-

Explore how energy-efficient inverters can significantly reduce operational costs and enhance system performance. ↩ ↩

-

Different pumps have unique inverter needs based on their operation and environment. ↩

-

Key factors include power matching, environmental compatibility, and control features. ↩

-

Oversizing or undersizing the inverter can lead to inefficiency or system failure. ↩

-

Certifications ensure safety, reliability, and environmental compliance. ↩

-

Common mistakes include incorrect power rating selection and ignoring environmental factors. ↩