In the competitive solar energy market, selecting a reliable factory for IP65 solar pump inverters is a crucial step toward ensuring product quality, long-term durability, and seamless operation. Manufacturers like Hober, renowned for their Hybrid Solar Pump Inverters, offer valuable benchmarks for advanced features, reliability, and efficiency. This guide outlines the key considerations when choosing a factory and highlights how top-tier products, such as Hober’s inverters, address market demands.

Why IP65 Protection is Essential

IP65-rated inverters are specifically designed for rugged environments, making them ideal for remote and outdoor installations. Solar pump inverters often operate in locations where constructing protective housing is impractical. Adding an external enclosure not only increases costs but can also trap heat, affecting system performance and lifespan.

An IP65 rating ensures the inverter is dust-tight and resistant to water jets, eliminating the need for additional housing. This allows the inverter to dissipate heat efficiently, even in extreme temperatures, ensuring consistent operation over the years. For solar pumps installed far from urban infrastructure, these factors are vital for reliable operation and cost efficiency.

Key Features of Hober’s Hybrid Solar Pump Inverters

When evaluating factories, consider their ability to offer products with modern, efficient designs. Hober’s inverters are an excellent example of what to look for, with features that include:

- Dual Power Input: Allows seamless use of solar and grid power, ensuring uninterrupted operation even in low sunlight conditions.

- Advanced MPPT Technology: Automatically optimizes energy usage by adjusting frequency based on sunlight intensity.

- User-Friendly Operation: Plug-and-play systems with no programming required, real-time monitoring via 3G/4G/WIFI, and an intuitive display showing voltage, current, frequency, and power.

- IP65 Waterproof Rating: Suitable for various environments without additional housing, which lowers installation costs and enhances system longevity.

- Built-In Data Logger: Tracks historical data and system issues, enabling preventive maintenance.

- Temperature Resilience: Operates efficiently in temperatures up to 60°C, making it ideal for extreme climates.

- Comprehensive Protection Features: Prevents issues like overcurrent, short circuits, and overheating, extending the inverter’s lifespan.

Factors to Consider When Choosing a Factory

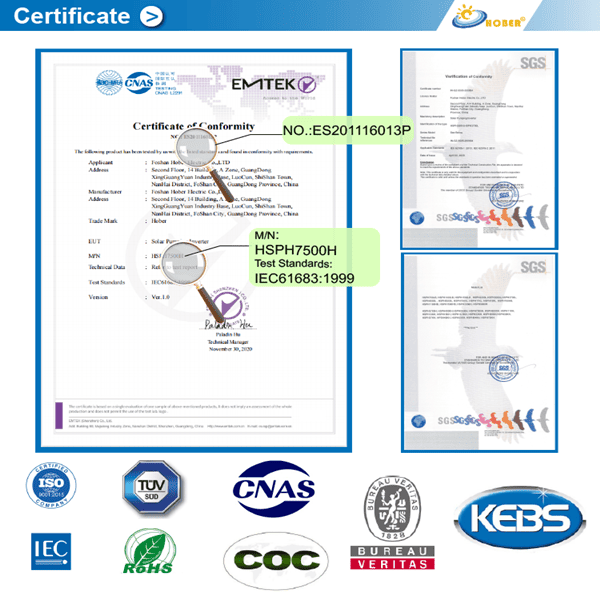

1. Quality Certifications

A factory’s certifications reflect its commitment to global safety and quality standards.

- What to Look For: Certifications such as CE, ISO 9001, and IEC ensure compliance with industry benchmarks.

- Why It Matters: Certified products are more likely to perform reliably, especially in demanding conditions like remote agricultural fields or industrial sites.

2. Product Range and Features

The best factories offer diverse product ranges with advanced features tailored to varying customer needs.

- Key Features to Prioritize: Look for MPPT efficiency, dual power input, IP65 waterproofing, and built-in monitoring systems.

- Example from Hober: Hober’s inverters include innovative features like plug-and-play functionality and remote control, setting a standard for ease of use and reliability.

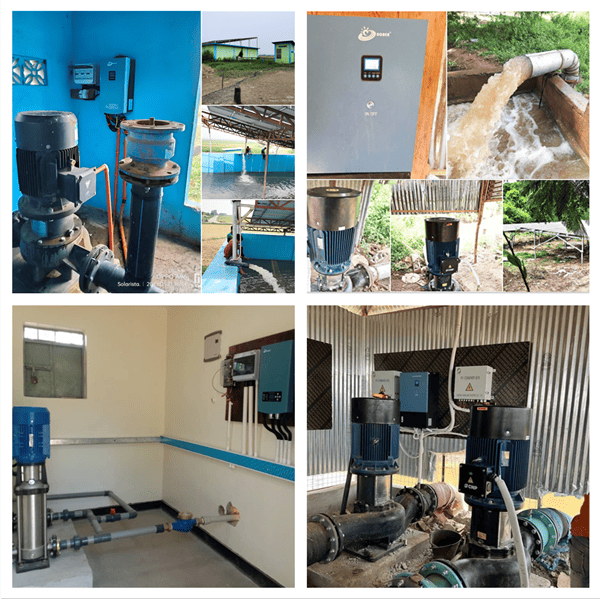

3. Reputation and Experience

An experienced factory with a proven track record is more likely to meet your quality and delivery expectations.

- Research Strategies: Check online reviews, testimonials, and case studies. Seek manufacturers like Hober, which has over 15 years of expertise in developing solar pump inverters.

- Industry Example: Reputable manufacturers often provide detailed documentation and product demonstrations to validate their claims.

4. After-Sales Support

Comprehensive after-sales support ensures that you have access to technical assistance and replacement parts if issues arise.

- What to Look For: Factories offering long warranty periods (e.g., 3–5 years) and dedicated support teams for troubleshooting and maintenance.

- Pro Tip: Evaluate the factory’s responsiveness during the inquiry phase to gauge their commitment to customer service.

5. Manufacturing Capabilities

A factory’s production capacity and quality assurance processes determine its ability to meet wholesale demands consistently.

- What to Assess: Monthly production volumes, lead times, and quality control measures.

- Critical Feature: For products like Hober’s IP65 inverters, rigorous testing ensures durability and reliability, even in extreme conditions.

6. Pricing and Payment Terms

While competitive pricing is important, prioritize quality and advanced features over the lowest cost.

- Best Practices: Compare quotes while considering the features offered. Factories that provide flexible payment options are more appealing for long-term partnerships.

7. Communication and Responsiveness

Effective communication is key to ensuring smooth transactions and addressing any concerns promptly.

- What to Expect: Factories should provide clear timelines, regular updates, and transparent communication about technical details.

Conclusion

Choosing the right factory for wholesale IP65 solar pump inverters is about balancing certifications, advanced features, reputation, and manufacturing capabilities. Products like Hober’s Hybrid Solar Pump Inverters exemplify what to look for: cutting-edge technology, rugged durability, and user-friendly design. By partnering with a reliable factory that offers these benefits, you can deliver high-quality, cost-effective solutions to your customers while ensuring long-term success for your business.

Other FAQ question

1. Why is IP65 protection important for solar pump inverters?

IP65-rated inverters are dust-tight and water-resistant, making them ideal for outdoor and remote installations. They eliminate the need for additional protective housing, which can trap heat and reduce lifespan. IP65 ensures durability and efficient operation, even in harsh environments or extreme temperatures up to 60°C.

2. What certifications should I look for in a factory?

Look for globally recognized certifications such as CE, ISO 9001, and IEC. These demonstrate the factory’s commitment to quality, safety, and compliance with international standards.

3. What advanced features should a solar pump inverter have?

Key features include:

- Dual power input (solar and grid).

- MPPT technology for optimizing energy usage.

- Real-time monitoring with displays for voltage, current, and frequency.

- Built-in data logging for troubleshooting.

- IP65 protection for outdoor use.

4. How can I assess a factory’s reputation?

Research online reviews, customer testimonials, and case studies. Manufacturers with extensive industry experience, such as Hober, are often more reliable due to their established track record.

5. Why is after-sales support critical?

After-sales support ensures technical assistance, timely replacement parts, and warranty coverage. Factories offering 3–5 years of warranty and dedicated customer support provide peace of mind for wholesale buyers.

6. What are the benefits of IP65 inverters for remote installations?

IP65 inverters can withstand outdoor elements like dust and water, operate without additional housing, and maintain optimal heat dissipation. This reduces installation costs and ensures consistent performance, even in isolated locations.

7. What role does pricing play in choosing a factory?

While competitive pricing is important, prioritize features like durability, efficiency, and certifications over the lowest cost. Factories offering flexible payment terms and bulk discounts are ideal for long-term partnerships.

8. How do I ensure effective communication with a factory?

Choose a factory with transparent communication, quick response times, and regular updates during production. Clear communication reduces the risk of delays and misunderstandings.