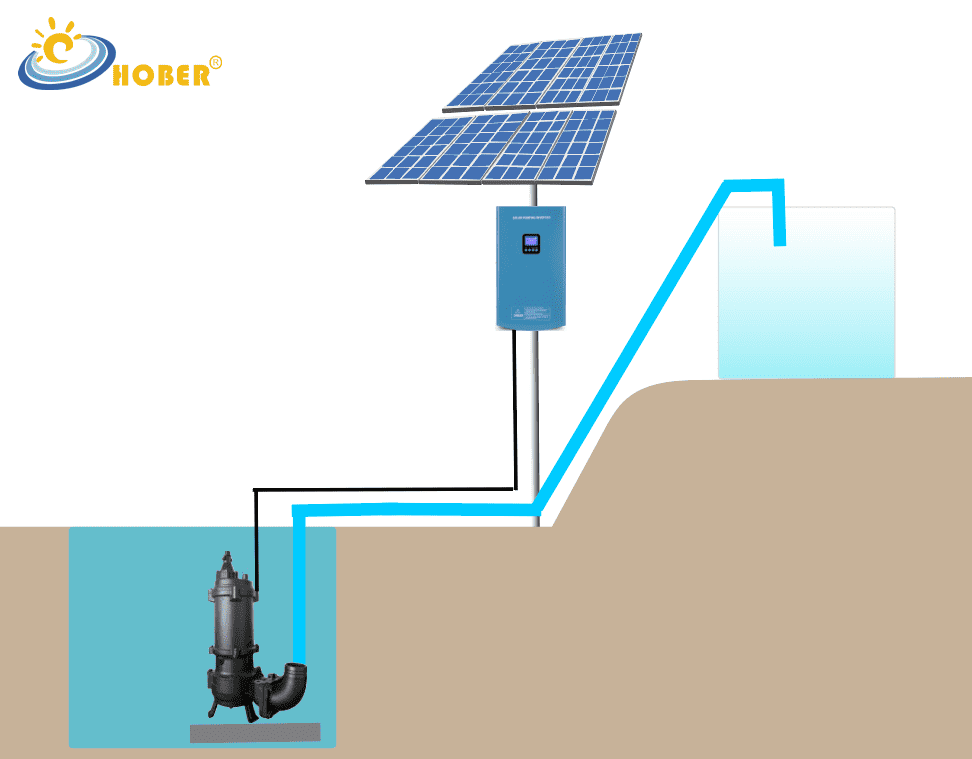

Solar Sump Pump

What Are Solar Booster Pump application ?

Agricultural Fields

Construction Sites: Helps in dewatering.

Remote Areas: Manages water where electricity is scarce.

Outdoor Ponds: Regulates water levels.

Mining Operations: Drains groundwater.

River and Lake: Extracts water for Irrigation purposes.

Hober Solar Booster Pump Benefits

Eco-friendly Solution: Utilizing solar energy, Hober’s sump pump reduces carbon footprint and promotes sustainable water management.

Low Head, High Flow Rate: Specifically designed for efficient irrigation, with an optimized balance between lift height and water flow.

Reliable in Remote Locations: Ideal for areas with inconsistent or no access to the electrical grid, ensuring uninterrupted operation.

Durable and Robust: Manufactured with the latest technology to withstand harsh environmental conditions, ensuring longevity.

Comprehensive Support: Backed by Hober’s renowned after-sales service, providing reliable technical assistance and training.

Condiderations when buying Solar Sump Pump

Water Source

Different depth and Flow ,Different models

Control by Cellphone

Water Sensor

Dry-run protection by software or sensor

More Than a Solar Sump Pump Manufacturer

At Hober, we are committed to exceeding standard delivery by offering exceptional customer service. We take pride in delivering timely support, adhering to high ISO 9001 standards, and providing quality product to your high level needs. This commitment to excellence has solidified our reputation as a premier manufacturer of solar sump pump

Model Selection Guide

Uncertain about the ideal Solar pump model ? Allow us to steer you toward the Depth and flow that harmonizes with your project requirements.

Dedicated Technical Support

Have question or concerns about our solar pump ? We’re here to help to design system, whether that means addressing inquiries or dispatching an engineer to your project site for hands-on assistance.

Solution Design

offer free design for solar water pump system solutions, which can be customized to meet the requirements of special projects.

Training

Provide online training, as well as 24-hour online after-sales service to ensure our customers receive the support they need.

Why Choose Hober Solar Sump Pump ?

At Hober, we’re dedicated to enhancing your business with the solar sump pump . Our unparalleled expertise in the solar industry sets us apart from the rest. The success of your venture hinges on product quality, and we’re your reliable source for excellence, ensuring your solar pump project’s success.

Fast Shipping, Flexible Minimum Order Quantity

One-stop Solar Pump solutions

20+ patents about inverter and pump Technical

OEM/ODM experience 10+ years

Regular technical trainning

High efficient sales team with Professional experienced

Features of the Solar Sump Pump

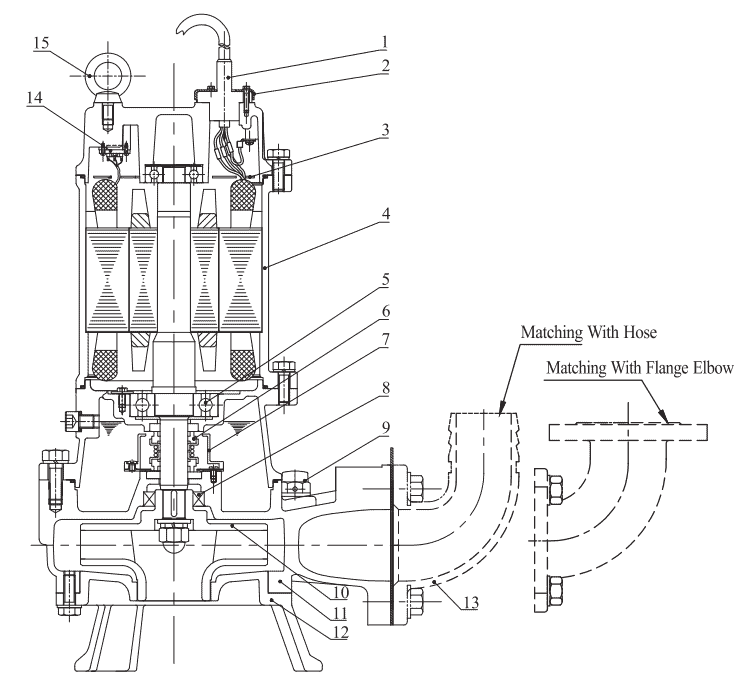

Impeller Design: Carefully matched pump body and impeller ensure optimal flow, high efficiency, a flat power curve, and minimal risk of overload. The precision balance of the impeller ensures minimal vibration and smooth rotation.

Motor Design: The submerged motor boasts IPX8 protection, F-class insulation for heat resistance, and is cooled efficiently when submerged. This ensures low actual temperature rises, promoting longer insulation life.

Shaft Seal: The motor’s shaft is protected by two or three cascading mechanical seals. One is immersed in the medium, preventing water intrusion into the oil chamber. The other seals prevent oil from entering the motor.

Oil Chamber: The chamber contains appropriate mechanical oil and two mechanical seals. It acts as a barrier preventing medium intrusion and also cools and lubricates the friction surfaces of the seals.

Bearings: The bottom bearing provides reliable support to the pump-motor shaft. Considering radial, axial forces, and pulsating loads during operation, the bearing consists of two to three different types, ensuring smooth operation and extended lifespan.

Cable and Sealing:

The cable is encased in a sewage-resistant rubber sheath, designed for reliable operation under full-load power in 40°C environments.

Seals are present between the rubber sheath and motor cover to prevent medium infiltration.

In the event the rubber sheath is damaged, the vulcanized rubber between the sheath and the core still prevents medium infiltration.

Motor Housing: The housing, made up of the base, bearing seat, and motor cover, boasts reliable static sealing, with each unit undergoing rigorous air pressure testing to ensure its watertight nature.

Internal Safety Measures:

Oil-water Probe: Installed in the oil chamber to detect leaks, triggering an alarm when detected.

Water Entry Probe: Positioned inside the motor chamber, it detects oil leaks into the motor.

Thermal Sensor: Found within the motor’s winding, it sends an alarm and stops the pump if the motor overheats.

External Control System: A dedicated electrical control cabinet processes internal signals for control, protection, audible and visual alarms, and automation for single or multiple pumps. Users providing their control cabinets should contact the company for guidance on installing protective controllers.

Handling: The pump comes with dedicated handles for transport. Pulling the cable during transport is strictly prohibited, as it may break the seal between the cable and motor cover, leading to water intrusion.

Performance Curves and Parameters: The curves on the performance graph indicate the pump’s recommended usage range. Care should be taken to ensure the pump operates within the motor’s rated power range to avoid motor burnout.

Advantage of the Solar Sump Pump

Special Solar Sump Pump Cable Manufacturing Process: Our unique technique ensures full protection against motor interior infiltration even if there’s damage to the cable surface or the cable’s front end is submerged. Water can’t seep in through the tiny gaps between the wires.

Dedicated Submersible Motor Design for Solar Sump Pump: Engineered with IPX8 protection, it boasts a Class F insulation that allows for a higher temperature rise. However, the motor benefits from efficient submersible cooling, resulting in a lower actual temperature rise. This prolongs the motor’s insulation lifespan and guarantees an automatic power cut-off under abnormal conditions.

Dual Mechanical Seal for Solar Sump Pump: Implemented with an additional external skeletal oil seal. The seal chamber has a uniquely designed oil riser ensuring adequate lubrication for the mechanical seal even at low oil levels, extending the seal’s life. This ensures reliable sealing performance and guarantees the product’s safe and continuous operation. This particular technology is patented by Tsukimi Seisakusho Corporation.

Automatic Air Release Valve for Solar Sump Pump: Ingeniously designed at the pump’s exit, this eradicates the hassle of manually releasing air trapped inside. When the pump is operational, it automatically discharges air, ensuring water outflow and preventing issues caused by air retention within the pump.

Solar Sump Pump Impeller Design: The impeller is designed with closed and open shapes, featuring dual flow paths. Thanks to the symmetrical flow channels, it has good balance, steady operation, and minimal vibration. This enhances the product’s longevity. Its flow-through capability is robust, and the tested efficiency exceeds national standards, leading to energy conservation and reduced wastage.