Solar Water Purifiers for Sustainable Health and Growth

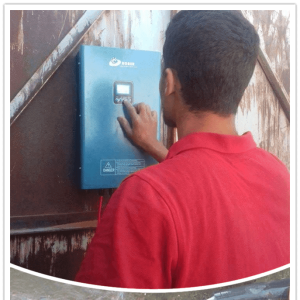

Solar water purifiers use the sun’s energy to eliminate contaminants from water, making it safe for consumption. From simple solar distillation units to sophisticated photovoltaic systems, the technology is diverse and adaptable to various needs.