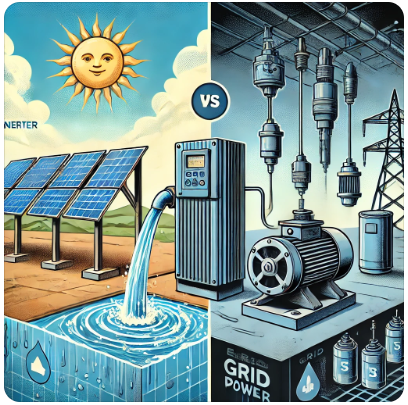

When choosing the right technology for motor control, understanding the difference between a solar pump inverter and a VFD (variable frequency drive) is essential. While both devices control the speed of electric motors, their power sources, applications, and operational mechanisms differ significantly. In this article, we’ll explain how each works and help you choose the best option for your specific needs.

A solar pump inverter is designed to run on solar power, converting direct current (DC) from solar panels into alternating current (AC) to drive water pumps, ideal for off-grid water systems. In contrast, a VFD (variable frequency drive) is used in grid-powered systems to control motor speed by adjusting the frequency and voltage of the AC power supplied to the motor. Each technology has specific applications and benefits depending on energy availability and use case.

Now, let’s dive deeper into the differences between a solar pump inverter and a VFD to help you make an informed decision.

1. What is a Solar Pump Inverter?

A solar pump inverter is a device that converts the DC (direct current) generated by solar panels into AC (alternating current), which powers water pumps. This system is ideal for agricultural irrigation, remote water supply, and areas without access to the electrical grid. Solar pump inverters often come with maximum power point tracking (MPPT), ensuring the solar panels are operating at their highest efficiency.

- Use Case: Typically, solar pump inverters are used in remote locations where the cost of running power lines is prohibitive, or where grid power is unreliable. They optimize water pumping during sunny conditions, making them popular for off-grid irrigation systems.

2. What is a VFD (Variable Frequency Drive)?

A VFD controls the speed and torque of an AC motor by varying the input frequency and voltage supplied to it. Unlike solar inverters, VFDs are typically powered by the grid or other AC sources. They are widely used in industrial settings for systems like conveyor belts, fans, and pumps, where speed control is critical for process efficiency.

- Use Case: VFDs are popular in commercial and industrial settings, where precise motor control is needed. They improve energy efficiency, reduce mechanical stress on systems, and extend the lifespan of motors.

3. Key Differences Between Solar Pump Inverter and VFD

- Power Source: Solar pump inverters are powered by solar energy (DC), while VFDs rely on grid electricity (AC).

- Primary Application: Solar pump inverters are used in off-grid water pumping systems, while VFDs are used in grid-powered motor control systems across various industries.

- Energy Efficiency: Solar pump inverters maximize the use of solar energy with MPPT, while VFDs focus on energy savings by adjusting motor speeds to match load requirements.

- Cost: Solar pump inverters are generally more expensive because of the technology required for solar power management, whereas VFDs are more affordable and widely used in standard AC applications.

4. How Do Solar Pump Inverters and VFDs Improve Efficiency?

Both technologies improve motor efficiency but in different ways:

- Solar Pump Inverters: Use solar power to provide energy savings, reducing reliance on grid electricity. The MPPT feature optimizes solar energy use, ensuring that pumps work efficiently even when sunlight varies throughout the day.

- VFDs: Improve motor efficiency by adjusting motor speed to match demand. By reducing the motor’s speed when full power isn’t needed, VFDs help save energy, reduce wear and tear, and improve system longevity.

5. When Should You Choose a Solar Pump Inverter vs. a VFD?

- Choose a Solar Pump Inverter if you are looking to power a water pump in an off-grid location with access to sunlight. It’s the ideal choice for farms, ranches, or rural areas without reliable grid power.

- Choose a VFD if you need precise motor control in a grid-powered system, such as in HVAC, manufacturing, or commercial settings where the motor’s speed needs to be adjusted frequently to optimize performance.

Summary

In conclusion, the choice between a solar pump inverter and a VFD depends on your power source and application needs. If you need an off-grid water pump powered by renewable energy, go with a solar pump inverter. For grid-powered motor control, especially in industrial settings, a VFD is the better choice. Each device offers unique advantages, improving efficiency and performance in different scenarios.

By understanding these differences, you can select the right system to suit your specific requirements.