Introduction

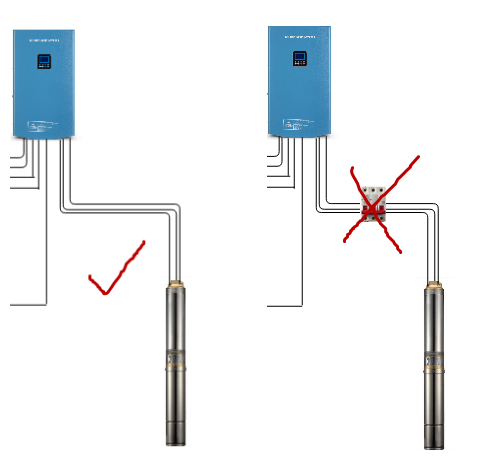

When installing a solar Pumping system or any setup involving inverters and pump motors, proper electrical connections are crucial. A common question arises: Is it safe to place a breaker between the inverter’s AC output and the pump motor? The short answer is no. Doing so can lead to a range of problems that can damage both the inverter and the pump motor.

In this article, we’ll explore why it’s forbidden to connect a breaker between the solar pump inverter’s AC output and the pump motor. We’ll break down the technical reasons behind this and offer safer alternatives for connecting your inverter to a pump motor.

Quick Answer

Connecting a breaker between an inverter’s AC output and a pump motor can lead to high inrush currents, loss of soft start functionality, and risk of phase imbalance, potentially damaging both the inverter and the pump motor.

Why Connecting a Breaker Can Be Dangerous

1. High Inrush Current

When an inverter is connected directly to a pump motor, the inverter can gradually ramp up power, ensuring a smooth start. This gradual increase in power prevents sudden surges, also known as “inrush currents,” that can damage electrical components.

However, if you place a breaker between the inverter and the motor, and this breaker is initially open:

- The inverter will start and reach its operating frequency (usually 50 Hz).

- When the breaker closes, it connects to the pump motor abruptly.

- This sudden connection causes a high inrush current, which can overload the inverter and motor.

High inrush currents can lead to overheating, increased wear and tear on motor windings, and potential failure of both the inverter and the motor. Over time, these surges reduce the lifespan of the system components.

2. Loss of Soft Start Functionality

Many inverters are equipped with a soft start feature. This feature gradually increases the voltage and current to the pump motor, allowing for a smooth startup. Soft starts reduce mechanical stress on the motor and lower the risk of electrical surges that can damage system components.

If a breaker is installed between the inverter and the motor:

- The soft start feature of the inverter is bypassed.

- The motor receives an immediate and full voltage surge once the breaker is closed.

- This sudden influx of power can cause a mechanical and electrical shock to the pump motor.

Without the soft start, the pump motor experiences a jarring start-up, which can lead to mechanical damage, increased maintenance costs, and potential system downtime.

3. Risk of Phase Imbalance

A breaker can sometimes malfunction, resulting in only partial connection of phases. For a three-phase system:

- The breaker might connect only two phases, leaving one unconnected.

- This situation creates an output phase failure or phase imbalance.

Phase imbalance can be detrimental to both the inverter and the pump motor:

- The motor may not start correctly or may run inefficiently, leading to overheating.

- The inverter can detect this imbalance as a fault, shutting down the system or, in the worst case, suffering damage due to unbalanced electrical loads.

This phase imbalance not only reduces the efficiency of the motor but also increases the risk of damage to the electrical system.

Safe Alternatives for Connecting Inverters to Pump Motors

To avoid the risks associated with installing a breaker between the inverter and the pump motor, consider these safer alternatives:

1. Use a Soft Starter or VFD (Variable Frequency Drive)

Instead of a breaker, use a soft starter or a Variable Frequency Drive (VFD). These devices control the power ramp-up process, ensuring a smooth start-up for the pump motor. They help in:

- Reducing inrush currents

- Providing smooth acceleration

- Protecting the motor and inverter from sudden electrical surges

2. Direct Connection with Proper Overload Protection

Connect the inverter directly to the pump motor but include appropriate overload protection devices. Circuit breakers or fuses rated for the specific motor and inverter can be installed upstream to protect the system from overloads without interfering with the inverter’s soft start functionality.

3. Regular Maintenance and Monitoring

Ensure that your inverter and pump motor system is regularly maintained. Include checks for phase balance and ensure all protective devices are functioning correctly. This proactive approach can help prevent issues that might lead to system failure.

Conclusion

Connecting a breaker between the inverter’s AC output and the pump motor can cause high inrush currents, loss of soft start functionality, and phase imbalance. These issues can lead to damage and reduced lifespan of both the inverter and the pump motor. To ensure a smooth and safe operation, it’s advisable to use soft starters, VFDs, or proper overload protection while directly connecting the inverter to the pump motor.

By following these guidelines, you can protect your solar power system or any inverter-driven setup, ensuring efficient and long-lasting operation.

Frequently Asked Questions (FAQ)

Q1: Can I use a breaker for safety reasons?

A1: While breakers are essential for safety, they should not be installed directly between the inverter’s AC output and the pump motor. Instead, install breakers upstream or use dedicated motor protection devices like soft starters or VFDs.

Q2: What happens if my system experiences a phase imbalance?

A2: Phase imbalance can cause inefficient motor operation, overheating, and potential damage to the inverter. It’s crucial to maintain a balanced electrical load to ensure safe operation.

Q3: What is the role of a soft starter in motor connections?

A3: A soft starter gradually increases the voltage to the motor, allowing for a smooth start-up and reducing mechanical and electrical stress. This helps protect both the motor and the inverter from sudden surges.